Jiangsu Jiali New Material Technology Co., Ltd. , https://www.jlmaterial.com

What Are the Key Benefits of Oil Seals?

Oil seals play a critical role in the daily operations of most factories and a broad spectrum of industrial and commercial machinery. Available in both imperial and metric sizes, they come in single and double-lip designs, making them versatile for different applications. These seals are essential for motors, hydraulic systems, pistons, and pumps, ensuring the protection of internal components by preventing contamination and retaining lubricants. Depending on your specific requirements, there are numerous configurations, sizes, and materials to choose from. To learn more about oil seals, their composition, and the benefits they bring to your equipment, keep reading.

---

An oil seal serves two primary functions: retaining lubricants and preventing the ingress of dirt and contaminants into moving components. This crucial function is achieved between surfaces in relative motion, such as a shaft or bearing inner ring and a housing. Properly installed, oil seals can also reduce the risk of seal leakage and maintain the lubricity of bearings, ensuring the smooth operation of rotary shafts and their associated bearings.

A standard oil seal typically comprises three main components: an outer ring, the sealing element, and a spring. The external metal ring provides structural integrity and stability to the seal, fitting snugly into the bore or groove. Attached to this ring is the sealing element, which is the flexible inner portion of the oil seal—often an O-ring—that prevents fluid leaks between the shaft and housing. A spring ensures consistent pressure, deforming the O-ring to create a reliable seal while applying radial force to the shaft.

Oil seals differ in materials and types depending on their intended application. Some common materials include:

- **Nitrile Buna-N 70**: Often referred to as NBR, this material is compatible with many environmental conditions and is cost-effective, making it a popular choice in industries. It performs well in temperatures ranging from -30°F to 250°F and is resistant to water, hydraulic fluids, gas, silicone, vegetable, and animal oils.

- **Fluoropolymer (FKM/Viton®)**: Ideal for high-temperature applications up to approximately 400°F, these seals exhibit excellent resistance to solvents, gases, and petroleum or transmission oils. They are widely used in harsh environments where durability is paramount.

- **Silicone (VMQ)**: Known for its versatility, silicone maintains performance in temperatures from -140°F to 392°F. It is resistant to adverse weather conditions, UV exposure, and ozone, making it a go-to material for the healthcare, food, pneumatic, and hydraulic industries.

- **Polyacrylate**: Combining affordability with high performance, polyacrylate is resistant to oxidation and heated oil, functioning effectively in temperatures from -25°F to 300°F. It finds applications in vehicle transmissions, shaft seals, and O-rings.

---

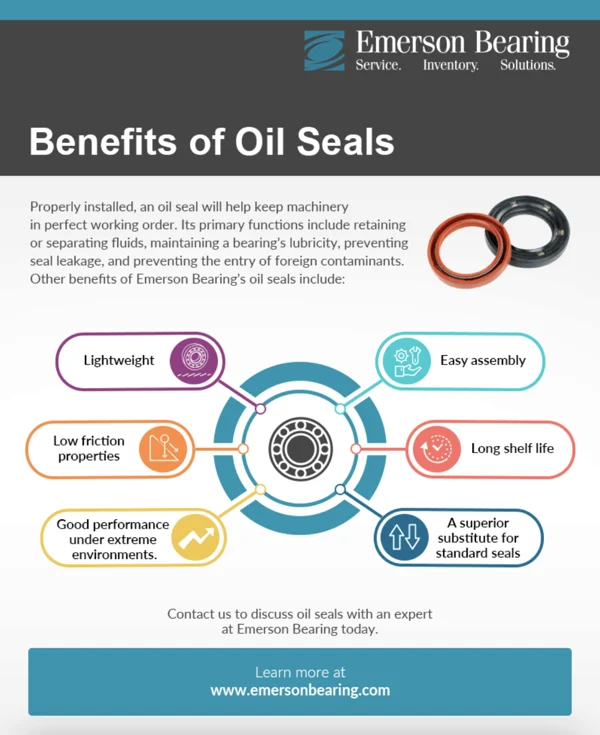

Oil seals offer several advantages that make them indispensable in modern machinery:

- **Low Friction**: The lubrication within the seal minimizes contact between the seal lip and the rotary shaft, reducing the risk of wear and tear.

- **Compact and Lightweight Design**: Despite their small size, oil seals are robust and capable of enduring harsh conditions.

- **Rugged Performance**: These seals maintain their integrity even under extreme temperatures and challenging environments.

- **Ease of Installation**: Oil seals are straightforward to install and replace, requiring minimal downtime for maintenance.

- **Versatility**: Whether your application requires dry or lubricated environments, oil seals can adapt accordingly, offering enhanced functionality.

---

---

**Why Choose Emerson for Your Oil Seal Needs?**

Selecting high-quality oil seals for roller bearings, precision bearings, and other applications is a significant decision. At Emerson Bearing Company, we don’t just manufacture oil seals—we leverage over 50 years of expertise in bearings and related components to guide you toward the perfect solution for your specific needs. Whether you require a standard part or something more complex, our extensive inventory and global sourcing network ensure timely delivery. Our commitment extends beyond products; we offer 24/7 customer support and same-day shipping options to enhance your experience.

Our oil seals cater to a diverse range of industries, both domestically and internationally. Here’s what you’ll find in our online product catalog:

- **Garlock Isolator-Style Oil Seals**

- **Metric Oil Seals**

- **Inch Measurement Oil Seals**

Contact us today to explore how Emerson can meet your oil seal requirements and discover additional services tailored to your needs.

---

At Emerson Bearing Company, we pride ourselves on delivering excellence in every aspect of our business. Let us help you optimize your machinery and streamline your operations with the right oil seals.

Water-based Aluminum Paste