Jiangsu Jiali New Material Technology Co., Ltd. , https://www.jlmaterial.com

What Are the Key Benefits of Oil Seals?

Oil seals play a crucial role in the smooth functioning of many factories and a variety of industrial and commercial machinery. Available in both imperial and metric sizes, these seals come in single and double lip designs to suit different applications. Motors, hydraulic systems, pistons, and pumps rely on oil seals to shield internal components from damage. Depending on the specific requirements, there are multiple material, size, and configuration options to meet diverse needs. Learn more about oil seals, their composition, and the significant advantages they bring to your equipment.

## What Exactly is an Oil Seal and What Components Does It Have?

An oil seal serves two main functions: retaining the lubricant inside and preventing dust and contaminants from entering moving parts. This separation must occur between surfaces that move relative to each other, typically a shaft or bearing inner race and a housing. Properly installed, oil seals can prevent leaks and maintain the lubricity of a bearing, ensuring that the rotating shaft and its bearings function optimally.

A standard oil seal generally consists of three common parts: an outer ring, the sealing element, and a spring. The external metal ring provides structural support and stability to the oil seal within the bore or recessed groove. Attached to this ring is the sealing element. This flexible inner component, often an O-ring, stops any fluid leaks between the shaft and housing. A spring ensures continuous pressure, deforming the O-ring to create a reliable seal while applying radial force to the shaft.

Oil seals vary in materials and types depending on the application. Some common materials include:

- **Nitrile Buna-N 70 (NBR):** NBR is versatile and cost-effective, making it a popular choice for various industries. It performs well in temperatures ranging from -30° to 250° F and withstands exposure to water, hydraulic fluids, gases, silicone, vegetable, and animal oils.

- **Fluoropolymer (FKM or Viton®):** Ideal for high-temperature applications up to approximately 400° F, these seals are resistant to solvents, gases, and petroleum-based oils, making them suitable for demanding environments.

- **Silicone:** Silicone (VMQ) maintains performance in extreme temperature ranges (-140° to 392° F). It is resistant to weather conditions, UV light, and ozone, commonly used in healthcare, food industries, and pneumatic/hydraulic systems.

- **Polyacrylate:** Combining quality and affordability, polyacrylate is highly resistant to oxidation and heated oil, functioning effectively in temperatures from -25° F to 300° F. It is widely used in vehicle transmissions, shaft seals, and O-rings.

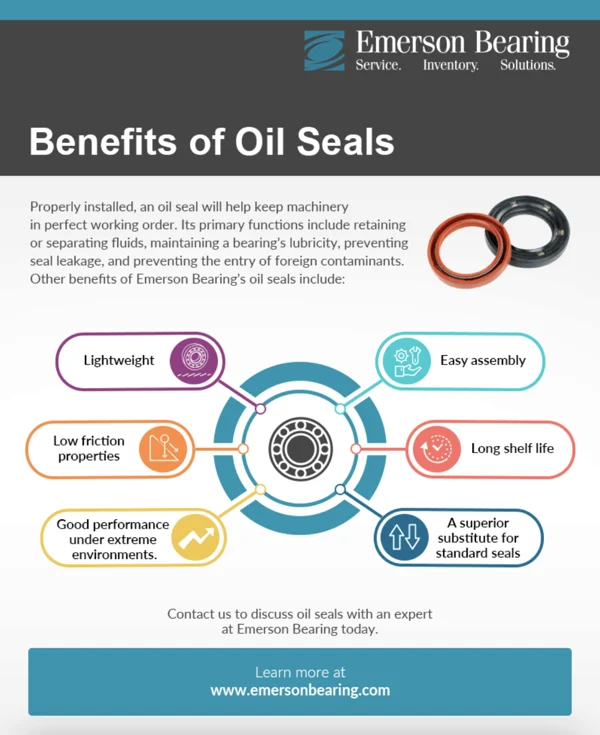

## What Advantages Do Oil Seals Offer?

Oil seals provide several benefits:

- **Low Friction:** The lubrication within the seal minimizes contact between the seal lip and the rotary shaft, reducing the risk of burning or wear.

- **Compact Size and Lightweight Design:** Despite their small size and lightweight construction, oil seals offer exceptional durability and endurance.

- **Rugged Performance:** These seals maintain their integrity even under harsh conditions or extreme temperatures, ensuring reliable sealing performance.

- **Simplified Construction:** Oil seals are easy to handle and install, taking just minutes to replace without requiring extensive dismantling of machinery.

- **Versatility:** Standard lip seals work well in dry environments, but oil seals offer enhanced functionality for applications needing more comprehensive protection.

## Why Choose Emerson for Your Oil Seal Requirements?

Selecting high-quality oil seals for your roller bearings, precision bearings, and more is a critical decision. At Emerson Bearing Company, we go beyond manufacturing oil seals. Drawing on over 50 years of expertise in bearings and related components, our team helps you find the ideal oil seals for your specific needs, no matter how complex your application. If we don’t have a particular part in stock, our global sourcing network ensures timely delivery of premium products. Our goal is to provide a seamless customer experience, from initial consultation and budgeting to oil seal selection and expedited shipping with same-day options.

Emerson’s oil seals cater to a broad spectrum of industries both locally and internationally. Here are some examples from our online product catalog:

- Garlock isolator-style oil seals

- Metric oil seals

- Inch-measurement oil seals

We also prioritize exceptional customer service, offering round-the-clock support. Contact us to explore our oil seals and additional services.

---

Feel free to reach out if you need further details or assistance in choosing the right oil seal for your application. We’re here to help!

Water-based Aluminum Paste