Fighting Water Main Breaks with Carbon Fiber Innovations As summer approaches, cities in colder climates are dealing with the lingering effects of a brutal winter. Record-breaking low temperatures and heavy snowfall have taken their toll, and now the warmer weather is exacerbating the situation. Snowmelt runoff and thawing grounds are triggering water main breaks across various regions. This season, commonly known as "water main break season," continues to pose a significant challenge globally. In Prince Albert, Saskatchewan, a persistent water main break has flooded local streets for over a month, causing disruptions and concerns among residents. Unveiling the Causes of Water Main Failures One of the primary culprits behind water main breaks is freeze/thaw cycles. As the ground thaws, uneven settlement occurs, causing shifts in the soil beneath the pipes. Many water main failures this season are linked to severe weather conditions and aging infrastructure. Some pipes are nearly a century old, and their condition has only worsened due to the extreme cold last winter. In Prince Albert alone, there have already been 19 water main breaks this season, with more expected in the coming weeks. City authorities are working diligently on a comprehensive plan to tackle these issues, recognizing that the harsh winter has put immense pressure on the city’s underground systems. Battling the Growing Problem of Corroded Pipes Corrosion in pre-stressed concrete cylinder pipes (PCCP) costs the U.S. water and wastewater systems over $50 billion annually, according to a 2002 study. North America experiences approximately 850 water main breaks every day, amounting to an annual repair cost surpassing $3 billion. These leaks result in the loss of around 2.5 trillion gallons of potable water annually, which represents roughly 17% of all water pumped in the U.S. A staggering 90% of this water loss can be traced back to corrosion-related issues tied to aging pipes. A 2012 study by Utah State University found that 43% of water mains in the U.S. are between 20 and 50 years old, while 22% are older than 50 years. Unfortunately, nearly half of the one million miles of pipelines beneath American streets are nearing the end of their operational lifespan. Replacing these systems is projected to cost over $1 trillion in the next 25 years. However, given the current lack of sufficient funding, there is an urgent need for solutions that can extend the life of existing PCCP infrastructure. HJ3’s CarbonSeal Carbon Fiber Solution HJ3’s CarbonSeal carbon fiber presents a practical and effective solution to these challenges. Consider the case of a cracked water pipe at a coal-fired power plant. The internal concrete lining of a 120-inch diameter pipe, designed to supply water to the plant’s cooling towers, developed cracks. Water seeping into the pipe caused corrosion of the pre-stressed wires within. As these wires deteriorated, the pipe’s ability to handle internal hoop stresses diminished. Faced with the high cost of replacing the entire pipe, the power plant decided to repair the 750 feet of pipe using HJ3’s CarbonSeal system. The CarbonSeal Repair Process The repair began with an abrasive blast on the pipe’s surface, followed by injecting polyurethane foam into the leaks. The pipe surface was then primed, and the saturated CarbonSeal carbon fabric was carefully applied. A protective topcoat was added until achieving a pin-hole free surface, ensuring the system was completely impermeable. Incredibly, all 750 linear feet of pipe were successfully repaired in just 11 days, restoring its capacity to withstand internal hoop stresses. This method saved 50% compared to other repair techniques and a substantial 65% compared to replacement costs. Additionally, it prevented six tons of concrete from being dumped in landfills. After eight years in operation, the system has performed exceptionally well, meeting expectations. The client expressed great satisfaction with HJ3, praising the invaluable support provided during the design calculations, engineering drawings, termination details, and on-site supervision throughout the project. Discovering CarbonSeal Reinforcement Systems If you're facing the task of repairing an underground pipe and want to learn more about HJ3's CarbonSeal reinforcement systems, feel free to reach out to HJ3 at [contact information]. †††custom aluminum foil food lunch box, custom pizza boxes ,custom pizza slice box ,aluminum foil lunch box ,Takeaway box Qingzhou Xincheng Packaging Co., LTD , https://www.qzxcbc.com

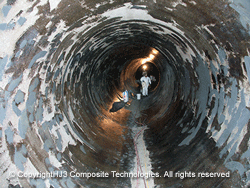

![PNM-1[1]](http://bsg-i.nbxc.com/blog/0cea1ad9232aeaed06638a149fc83342.jpeg)