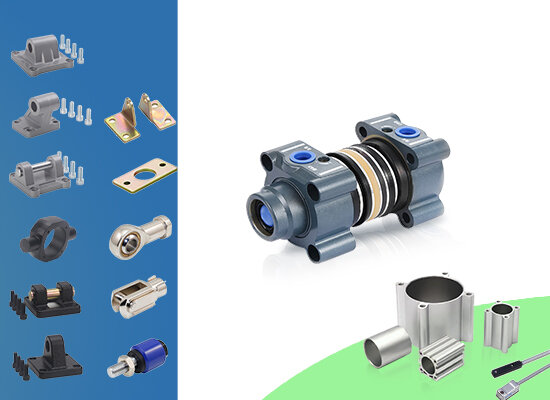

Pneumatic Cylinder Accessories Air cylinder accessories of different models and different standards are generally not interchanged. When ordering Pneumatic Cylinder accessories, please note the specifications and parameters of the corresponding cylinder. If the standard and model of the cylinder are same, the cylinder accessories can be used interchangeably.Pneumatic Cylinder Tube. Pneumatic cylinder is the executing component in pneumatic systems, mainly used to convert the pressure energy of compressed air into mechanical energy, generating linear or oscillatory motion. The construction of pneumatic cylinders is complex and includes multiple key components. Below are some common components and their functions: Cylinder Barrel: This is the main body of a cylinder, typically a cylindrical container used to accommodate pistons and other internal components. The cylinder barrel must be strong enough to withstand the pressure of compressed air inside. Piston: located inside the cylinder and in close contact with the inner wall of the cylinder barrel. When compressed air enters the cylinder, the piston moves inside the cylinder barrel, generating thrust or tension. Piston Rod: The part that connects the piston to the external mechanical structure and is used to transmit the linear motion of the piston. End caps/caps: fixed at both ends of the cylinder barrel, sealing the internal space of the cylinder and supporting the piston rod and other components. The front cover usually includes a guiding component for the piston rod. Seals: Used to prevent gas leakage and ensure smooth movement of the piston within the cylinder barrel. It mainly includes piston sealing rings, rod sealing rings, and dust sealing rings. Guide bushing: Helps the piston rod maintain the correct direction of movement, reducing friction and wear. Buffer Device: Some cylinders are equipped with buffer devices to slow down the speed of piston movement when it reaches the end point, preventing impact and noise. Magnetic switches: Some cylinders have built-in or external magnetic switches used to detect the position of the piston and control the action of the cylinder. Exhaust Flow Control Valve: Sometimes integrated into the cylinder, it is used to regulate the exhaust speed and control the speed of the piston. These components work together to enable the pneumatic cylinder to effectively convert the energy of compressed air into the required mechanical motion. According to specific application requirements, pneumatic cylinders may also include other specially designed components to meet specific functional requirements. Pneumatic Cylinder Accessories,Pneumatic Cylinder Parts Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

Model

Stage

Frequency

Power

Voltage

Current

Airflow

Vaccum

Compress

Noise

Â

Â

HZ

KW

V

A

m3/h

mbar

mbar

dB(A)

810 H07

Single

50

4.3

345-415Δ

600-720Y

9.5Δ/5.5Y

530

-200

200

70

60

4.8

380-480Δ

660-720Y

9.5Δ/5.5Y

620

-160

160

74

The Advantages of Rexchip Blowers:

1. 100% oil-free, with insulation class F and protection class IP55.

2. Available in dual frequencies: 50Hz and 60Hz.

3. Constructed from die-cast aluminum ADC12 for durability.

4. Dual-purpose design suitable for both compressor and vacuum applications.

5. Low maintenance with sealed long-life bearings.

6. Smart and quiet operation for improved user experience.

7. ATEX explosion-proof motor available for all models; REXCHIP is the only manufacturer authorized to produce such motors.

8. IE2 and IE3 motors are available for certain models.

9. High-quality products at competitive prices.

10. Fast delivery times to meet customer needs.

Applications of Rexchip Blowers/Pumps:

Rexchip blowers are widely used across various industries including:

1. Aquaculture (fish and prawn aeration)

2. Wastewater treatment and sewage systems

3. Pneumatic conveying systems

4. Pharmaceutical machinery

5. Garment industry

6. Woodworking equipment

7. Plastic processing machines

8. Printing machinery

9. Textile production

10. Packaging systems

11. Paper processing

12. Industrial cleaning devices

13. Air knives

14. Dental suction equipment

Our Workshop:

Our Exhibition:

Our Certifications (CE, ISO & CCC):

About Rexchip Blowers:

For over 15 years, our team has specialized in manufacturing side channel blowers, also known as ring blowers, regenerative blowers, air blowers, or vacuum pumps. We provide belt-driven blowers and all necessary components for these units. Our product range spans from 0.12kW to 30kW, making us a reliable partner for diverse industrial needs. Each step of production—from tooling creation to die casting, machining, assembly, and painting—is handled in-house, ensuring strict quality control, cost efficiency, and timely delivery.

Grain Suction Colleation System Side Channel Vacuum Air Pump

Model No.: 810H07

Trademark: REXCHIP

Transport Package: Packed in Carton, Then Protected by Wooden Pallet

Specification: CE

Origin: Zhejiang, China

HS Code: 8481809090

Specification:Pneumatic air cylinder accessories mainly include cylinder mounting brackets, piston rod connecting joints, repair sealing parts, magnetic reed switch, as well as cylinder assembly kits and cylinder barrels, piston rods etc.Air Cylinder Tube.